IP66 Electrical Enclosures: Protection You Can Trust

If you're managing electrical installations in outdoor or harsh indoor environments, choosing the right enclosure is vital for safety and longevity. Among the various standards, the IP66 electrical enclosure stands out as a top-tier solution for protecting sensitive electronics. In this comprehensive guide, we’ll explore what makes the IP66 rating essential, how it compares to the IP65 electrical enclosure, and how to choose the best one for your needs.

What Is an IP66 Electrical Enclosure?

An IP66 electrical enclosure is designed to provide complete protection against dust ingress and high-pressure water jets from any direction. “IP” stands for Ingress Protection, a globally recognized rating standard defined by the International Electrotechnical Commission (IEC). The two digits following “IP” specify the level of protection:

-

The first digit “6” indicates total protection against dust.

-

The second digit “6” means the enclosure can withstand powerful water jets.

This makes IP66 enclosures ideal for outdoor applications or demanding indoor settings such as food processing plants, marine environments, and industrial factories.

Key Features of IP66 Enclosures

✅ Dust-tight Sealing

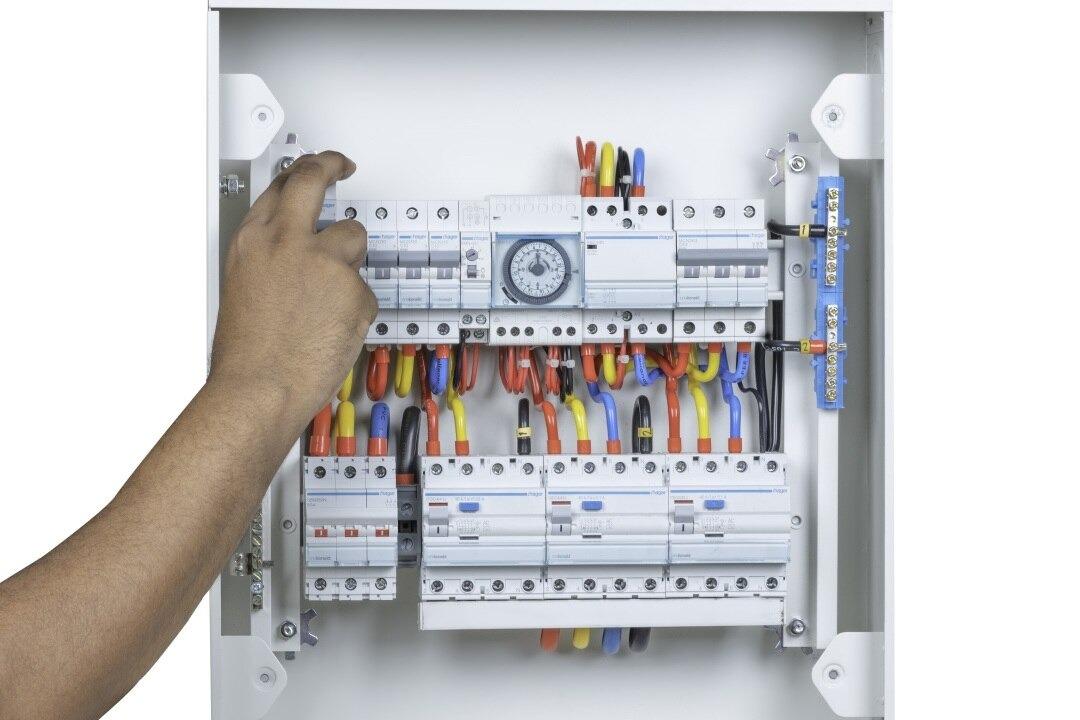

An IP66 electrical enclosure guarantees no ingress of dust, providing a safe environment for electrical components like circuit breakers, terminals, PLCs, and control systems.

✅ Water Resistance

The enclosure can endure high-pressure water jets (100 liters per minute) from a nozzle of 12.5 mm diameter at a distance of 3 meters. It ensures electrical safety even during intensive wash-downs or stormy conditions.

✅ Durability in Harsh Conditions

Constructed from materials like stainless steel, polycarbonate, or powder-coated aluminum, these enclosures resist corrosion, UV radiation, and impact.

✅ Versatile Applications

From solar power systems to outdoor control panels, IP66-rated enclosures are trusted for mission-critical applications that cannot afford downtime.

IP66 vs. IP65 Electrical Enclosure: What’s the Difference?

While both IP66 and IP65 electrical enclosures offer strong protection, there are subtle but crucial differences:

| Feature | IP65 Electrical Enclosure | IP66 Electrical Enclosure |

|---|---|---|

| Dust Protection | Complete | Complete |

| Water Protection | Low-pressure jets (6.3 mm nozzle) | High-pressure jets (12.5 mm nozzle) |

| Outdoor Suitability | Moderate | Excellent |

| Cost | Lower | Slightly Higher |

| Ideal Use Case | Covered outdoor & indoor | Harsh, fully exposed environments |

In short, if your application is exposed to heavy rain, hosing, or severe dust, an IP66 enclosure is the better choice.

Common Applications of IP66 Electrical Enclosures

🛠 Industrial Automation

Control cabinets for manufacturing machinery and robotics often require IP66 protection due to exposure to dust and coolant sprays.

⚡ Outdoor Electrical Panels

Used in construction sites, solar panel setups, and telecommunications towers to shield components from the elements.

🚿 Food & Beverage Industry

Washdown areas need enclosures that resist water ingress during frequent cleaning with pressure hoses.

🌧 Marine & Coastal Areas

IP66 enclosures prevent saltwater corrosion and protect against wind-driven rain and sea spray.

Choosing the Right IP-Rated Electrical Enclosure

To select the most suitable enclosure for your project, consider the following:

-

🌡 Environment: Is it indoor, outdoor, dusty, or exposed to water?

-

🔧 Material: Choose stainless steel for corrosion resistance, or polycarbonate for lightweight needs.

-

📏 Size & Mounting: Ensure the enclosure dimensions fit your equipment and provide enough ventilation or cable entry.

-

🧪 Compliance: Check certifications such as NEMA 4X, UL 508A, or RoHS, especially for industrial or North American markets.

Why IP66 Enclosures Are Worth the Investment

Although IP66-rated enclosures may be slightly more expensive than their IP65 counterparts, the long-term protection they provide often outweighs the upfront cost. The added defense against high-pressure water jets and complete dust ingress can prevent costly damage to electrical components, ensuring operational reliability and workplace safety.

Conclusion

Choosing an IP66 electrical enclosure ensures your equipment stays protected in the harshest environments. While the IP65 electrical enclosure offers solid protection, IP66 goes the extra mile—especially in applications exposed to heavy water jets and dust. Whether you're outfitting an industrial control system or an outdoor junction box, prioritizing ingress protection is a smart, long-term investment in safety and performance.

Always evaluate the environmental conditions and protection needs of your project. With IP66-rated enclosures, you can be confident in your equipment’s resilience and durability—no matter what nature throws at it.

¡Por favor activa el Javascript![ ? ]